Take the Guesswork Out of Monitoring Your Machine

The Total Monitoring System centralizes and simplifies your machine feedback

Centralize Monitoring

Centralize Monitoring

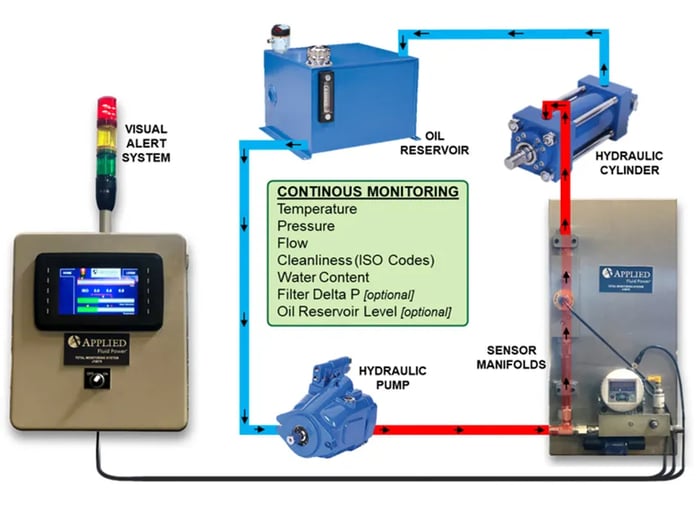

The TMS includes a touchscreen display that organizes all your sensors. Instead of searching around the machine for filter indicators, pressure gauges, flow meters, and cleanliness monitors, this information is displayed in a single place that is accessible to the operator. From this central point, alerts, options, and settings can be modified quickly. Additionally, critical settings are protected by an administrator password to prevent unauthorized changes.

Program Custom Alarms/Alerts

The end user can set up their own custom multi-level alarms using the built-in green, yellow and red lights, commonly known as a stacklight. The yellow alarm can be programmed to warn the user of a worsening issue, while the red alarm can be programmed to alert the user of a functional failure that may be causing damage to the machine. By using both alarms in tandem, you can address developing issues such as water ingress, contamination, elevated temperatures. The TMS can even shut down machines that have passed the point of no return.

The Total Monitoring System uses three built-in warning lights, known as a stacklight, to easily and quickly communicate status of the machine.

The Total Monitoring System uses three built-in warning lights, known as a stacklight, to easily and quickly communicate status of the machine.

Add What Sensors You Need

No two applications are exactly alike, so only choosing the sensors needed for your application is important. If your only concern is fluid cleanliness, a dedicated TMS with ISO cleanliness code readouts and customized alerts may be a good fit. However, if you need more information from your system including pressure, temperature, flow, etc., then these sensors can be easily added to the system. Applied Fluid Power represents a wide breadth of some of the largest sensor manufacturers in the world, so we can assist you in selecting the specific sensors for your applications needs.

Pick and Choose Sensors from Multiple Suppliers

Because the TMS works with a wide variety of sensor brands and products, you can pick the best available sensors for each condition you need to monitor. This is especially important because each supplier will offer unique features and benefits or may specialize in one particular sensor.

Customize Solutions to Challenging Applications

It can sometimes be challenging to add sensors to an existing fluid system. Pressure and return lines can be hard-plumbed or run in difficult-to-reach locations. For this reason, many of the sensor solutions in the TMS can be run in an offline loop, which we can supply separately if needed. We can also combine multiple sensors (pressure, temperature, flow, cleanliness, etc.) into a single sensor manifold to create fewer leak points and a more compact installation.

Easily Update Your System as Needed

All the alarms and alerts contained in the TMS are fully customized by the user. Authorized users can change what system conditions indicate a yellow alarm versus a red alarm. Most alarm thresholds have minimum and maximum settings, enabling the user to raise an alarm when a parameter rises above or falls below a specific threshold. This can be especially useful on lube circuits where minimum lube pressure is critical to maintain operation. On other fluid power systems, over-pressure events help identify potential damage to the system.

Monitor Your System!Our engineers have the product knowledge and industry experience to implement the TMS in your new or existing application. Contact us today to start collaborating on your machine design to get the TMS working for you. |

|