Why Use a Custom Hydraulic Manifold?

Custom designed manifolds can streamline the efficiency of a hydraulic machine

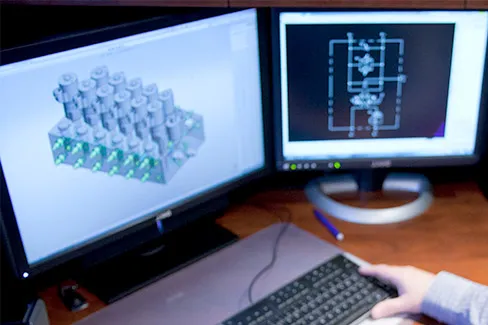

With collaboration from FluidTech. Image above provided by FluidTech.

Why use a custom hydraulic manifold?

It’s well known that manifolds are a common component that serve to simplify the hydraulic circuit by providing an optimized flow path for hydraulic fluid. They are so common, in fact, that many manufacturers sell industry-standard manifolds. These products have been designed for use in many different hydraulic systems.

However, many times these industry-standard manifolds simply don’t fit the bill. These applications require something more tailor-made, a custom hydraulic manifold designed for that specific application.

Computer design software allows engineers to create the perfect manifold for any application. (Image provided by FluidTech)

Computer design software allows engineers to create the perfect manifold for any application. (Image provided by FluidTech)

So how does a custom manifold differ from an off-the-shelf product?

Size efficiency/Non-standard shape

The shape of a standard manifold may not fit your machine, it could be too long, too tall, or too wide. This is especially troublesome on mobile machines where space is at a premium. A custom manifold, however, can be designed to fit the limited space more efficiently. For instance, a compact mobile machine may require a very long and thin manifold to fit into the design.

Custom circuitry

Depending on port orientation and valve selection, standard manifolds may “grow” too large or too oddly-shaped to install properly. Valves may be oriented in the wrong direction, forcing less efficient hose routing. Two hoses that could be routed together may end up on opposite sides of the manifold. Custom manifolds can be designed with specific valves and machine layout in mind, so the circuitry and the associated ports can be oriented and routed perfectly.

Exactly correct ports

The best valve for the machine may not fit a standard manifold. This may require a sub-optimal alternative valve. When designing a custom manifolds, the valves can be selected first, and the manifold machined to match, so there is no compromise.

Standard manifolds may also have too many or too few ports. Too many means wasted functionality and space, and too few means that in-line valves will have to be added downstream. Additional valves mean more install time, more hoses and fittings, and more oil pressure drop.

Cost effective solution

While looking at an individual machine, it might not seem worth the cost of designing a completely new manifold. However, if an original equipment manufacturer produces many machines a year, the cost savings of having a custom designed manifold become apparent.

FluidTech is here to helpThe experts at FluidTech have the technology and the know-how to design and manufacture the right manifold for your solution as part of our full system application design. We can also quickly turnaround a prototype as well as a full-run production product. What’s more, we can integrate all components and cartridge valves for you, reducing assembly time and errors. Contact us today to see how we can help you with your custom hydraulic design. |

|